Fullbrook Systems

Dissolver shaft DL

Convert the Laboratory DISPERMAT disperser into

a closed vertical Basket Mill - TML1 - 5 - 10 litre

a closed vertical Basket Mill -

Special advantages

● Milling chamber vol 65 ml

● Bead filling volume

50 - 80 %

50 -

● Excellent product

circulation via the dissolver disc and pump wheel

● Double walled grinding basket for cooling or heating

● Excellent dispersion results

The addition of the TML converts the DISPERMAT into a basket mill..

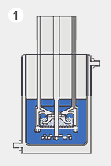

After the pre-dispersion stage is completed the dissolver shaft is replaced by the TMA basket mill without the need for any tools.

Basket mills are extremely efficient grinding systems comprising of a grinding basket that is lowered into the millbase for dispersion.

After the pre-

Basket mills are extremely efficient grinding systems comprising of a grinding basket that is lowered into the millbase for dispersion.

The double walled grinding basket filled with beads is lowered into the millbase.

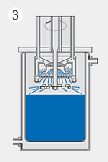

Cleaning the milling system is carried out with a suitable cleaning fluid in a separate container.

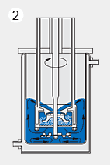

Intense circulation of the product is generated with the dissolver disc and integrated pump wheel. For assessment of the milling process – during dispersion – a product sample can be taken at any time.

When the milling process is complete, the grinding basket is raised. Product residue in the grinding basket is centrifuged out by briefly running the milling and the dissolver discs.

NEW: NANO-

From now on the modular basket mill TML is availabe with a NANO-

|

Type |

Container size l |

Product quantity l |

DISPERMAT® - |

|

| ||||

|

|

TML 1 |

1, 2, 3, 5 |

0,5 - |

FM | CN | CA 40 to 60 | AE 2 to 6 |

|

|

TML 5 |

5, 7, 10, 15 |

2,5 - |

FM 20 to 40 | CN 20 to 40 | AE 4, AE 6 to 11 |

|

|

TML 10 |

7, 10, 20, 30 |

3,5 - |

AE 7 to 11 |

|

|

TML 50 |

30, 50, 70 |

15 - |

AE 10 to 11 |

| Laboratory basket mills |

| Torusmill |

| LC30 LC55 LC75 |

| CV3 |

| TU |

| CA |

| CL 54 |

| CN |

| AE |

| CDS |

| VE |

| VL |

| CC |

| R11 |

| Containers |

| Impellers |

| Doughnut effect |

| What is dispersion |

| Scale up |

| Formulation |