Fullbrook Systems

DISPERMAT® SL-C12

DISPERMAT® SL-M EX

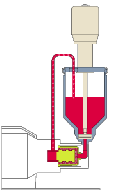

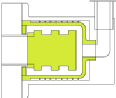

DISPERMAT® SL laboratory and pilot plant bead mills are closed,horizontal bead mills with high output and extremely low dead volumes in the millbase inlet and outlet pipes. During the dispersion process, the product to be dispersed is fed through the horizontal milling chamber and continuously dispersed.

The DISPERMAT® SL bead mills can be used for the pass as well as for the re-circulation process. After the dispersion, the integrated air pressure system presses the remaining millbase out of the milling chamber which allows an almost complete recovery of the dispersed material. Due to minimised dead volumes, even the smallest quantities can be dispersed with a high yield. Therefore the DISPERMAT® SL is an ideal tool for Research, Development and Quality Control.

Also,larger quantities can be processed within a very short period of time.In order to minimise the product loss, the mill base is transported directly from the supply vessel into the milling chamber.The dispersed product passes through the millbase separation (dynamic gap)and is recovered either in a vessel (pass method)or flows back into the supply vessel (re-circulation method).

The DISPERMAT® SL bead mills can be used for the pass as well as for the re-

Also,larger quantities can be processed within a very short period of time.In order to minimise the product loss, the mill base is transported directly from the supply vessel into the milling chamber.The dispersed product passes through the millbase separation (dynamic gap)and is recovered either in a vessel (pass method)or flows back into the supply vessel (re-

|

·

|

Quick and cost-

|

|

·

|

Quick and reliable transfer of laboratory development into production because of quantitative knowledge of the required mechanical power input.

|

|

·

|

Quality control and assurance of production.

|

|

·

|

Efficient control of incoming raw materials by measuring product properties relevant for the application.

|

|

·

|

Milling chamber volumes from 50 to 2000 ml

Power from 1,1 to 4 kW |

|

·

|

Explosion-

|

BEADMILLS

Vertical bead mill

| Laboratory basket mills |

| Torusmill |

| LC30 LC55 LC75 |

| CV3 |

| TU |

| CA |

| CL 54 |

| CN |

| AE |

| CDS |

| VE |

| VL |

| CC |

| R11 |

| Containers |

| Impellers |

| Doughnut effect |

| What is dispersion |

| Scale up |

| Formulation |