Wherever water is used to heat or cool a process, a risk of product leakage or carryover exists. Leak detection in process equipment such as heat exchangers and boilers are a vital part of safeguarding a chemical process. Immediate detection of leakage or carryover can be achieved by installing a Kemtrak photometer on the condensate line.

Benefits include:

* equipment protection (filters, boilers etc)

* product, process and environmental protection

* reduced downtime

* increased water re-

From a continuous monitoring of the process water for signs of contamination, conservation of water, energy and treatment chemicals is the result. The net benefit is a reduction in operating costs.

The monitoring of changes in color or UV absorbencies in the condensate is a reliable means of detecting leaks. Such measurements can detect trace levels of contamination allowing repairs to be scheduled before a catastrophic breakdown occurs.

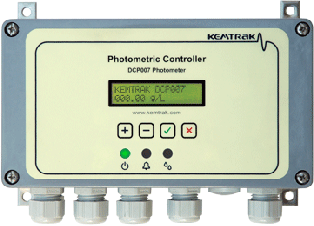

The Kemtrak DCP007 in-

A comprehensive range of both standard and custom designed industrial flow-

Leak Detection

| Kemtral TCP007 measurement principle |

| Kemtrak TCP007 turbidity meter |

| How it works |

| measurement |

| How it works |

| Measurement principle |

| Chemical general |

| Pharmaceutical |

| Petrochemical |

| Food and beverage |

| Pulp and Paper |

| Water and environment |

| Chemical concentration |

| Colour measurment |

| Interface detection |

| Leak detection |

| water in oil or fuel |

| Centrifuge |

| Filtration |

| Phase separation |

| Water detection |

| Chromographic separation |

| Colour ASTM saybolt |

| Interface detection |

| Water in fuel |

| Brewery |

| Dairy |

| Distillery |

| Food processing |

| Soft drinks |

| Wine |

| Alkali |

| Ozone |

| Chlorine dioxide |

| Chlorine |

| APHA Haze pt-c0 |

| Ozone |